Choosing the right circuit breaker can be challenging, as it involves safety, efficiency, and cost. And, many people find it difficult to choose between Air Circuit Breakers (ACBs) and Vacuum Circuit Breakers (VCBs).

If you are also feeling stuck between the two options, this will provide you with a simple and clear comparison to eliminate the confusion. The goal is to guide you towards an informed decision without stress. Let’s start!

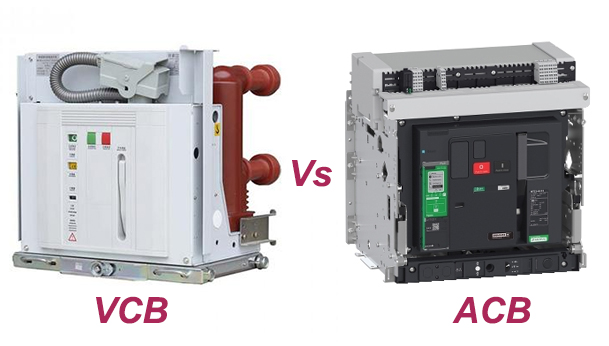

VCB Vs ACB

1) Understanding Air Circuit Breakers (ACB)

“An air circuit breaker (ACB) is a type of electrical safety device which, upon detection of an electrical fault or overload, disconnects the flow of electricity automatically.”

ACBs, which are typical in low and medium voltage systems, use air to interrupt current flow in the case of a fault. They protect devices against overcurrent, short-circuits, and earth faults. They are dependable, safe, and popular in industrial and commercial power systems.

Working Principle

The Air Circuit Breaker (ACB) uses air to extinguish the electric arc created during a fault. In the case of overload or short circuit, the trip unit can sense the condition and open its contacts. While disconnecting, the contacts will separate. And, due to this sudden separation, an arc will be produced.

Now the arc is driven to the arc chute (made up of several insulated metal plates). Basically, these plates will divide the arc and ultimately try to cool it down. In this process, air acts as an arc-quenching medium. The air flow cools the arc, reduces its temperature, and disperses the ionised particles, interrupting the electrical current.

Once the fault is cleared, the breaker can be reset. In doing so, it ensures the electrical systems are properly protected during abnormal and unsafe conditions.

Types of Air Circuit Breakers

Based on the usage and the ACB’s functionality, there are different types of ACBs. Each fulfils a specific purpose in safeguarding electrical systems.

i) Plain Break Type: This is the most basic type. It incorporates metal plates and open air to break the arc as the contacts separate.

ii) Magnetic Blowout Type: This variety incorporates magnets which stretch and push the arc to cool and separate from the contacts more rapidly.

iii) Air Chute Type: In this breaker, the chutes of the arc are split into thinner sections. These thin sections of arc extinguish more safely.

iv) Cross-Blast Type: This one employs powerful jets of air directed transversely to the arc. The jet stream quickly cools the arc as well as removes it from the contact region.

Applications of ACBs

- Industrial Power Systems

Found in manufacturing plants and big industrial facilities. Useful for the safe operation of high-voltage equipment.

- Power Generation Stations

Seen in thermal and hydro power plants as well as wind power plants. Moreover, safeguards generators and transformers from internal faults.

- Substations

Used extensively in indoor and outdoor substations. Provides a safe high-voltage current interruption.

- Commercial Buildings

Located in shopping centres, health facilities, and large office buildings. Offers dependable circuit protection with minimal servicing required.

- Railway Electrification

Employed in the power distribution framework for railways. Provides good control of heavy arcing during frequent operations.

- Renewable Energy Systems

Used for the protection of systems harnessing wind and solar energy. Designed for quick interruption of faults with little damage.

2) Understanding Vacuum Circuit Breakers (VCB)

“A vacuum circuit breaker, or VCB, is a type of breaker which interrupts the electrical current using a vacuum. An arc is produced when the contacts within the breaker open. This arc extinguishes very quickly in a vacuum since there is no air or gas to sustain it.”

Vacuum provides a high degree of insulation, which helps to extinguish the electrical current very rapidly. VCBs are used for medium-voltage applications. Well, circuit breaker vacuum is faster, safer, and has a longer lifespan than other types of circuits. In addition, they are also less maintenance-intensive than other breakers since there is no need for oil or air.

Working Principle

As a fault occurs, the circuit breaker opens, and the contacts within the vacuum chamber begin to part. Likewise, in an air circuit breaker, ionisation of metal vapours results in an arc. The difference, however, is that in a vacuum, there is neither air nor gas.

Because of this, the arc is extinguished as soon as the current stops. Furthermore, metal vapours condensing on the contact surfaces restore the insulating strength of the vacuum. This rapid recovery prevents any current from flowing, which is why the VCB is safe.

So, Vacuum Circuit Breakers are advantageous for medium voltage power distribution systems as they are efficient.

Properties of Vacuum for Arc Extinction

a) High Dielectric Strength: After an arc is made, the vacuum restores its insulating strength with great efficiency.

b) Rapid Arc Quenching: Absence of gas particles allows for instant breakage of arcs within a vacuum.

c) No ionisation: The lack of air or gas minimises ionisation, helping prevent reforming of the arc.

d) Metal Vapour Condensation: Any vaporised metal will get into the contacts, removing the obstruction for current flow cessation.

e) Stable Performance: The vacuum environment provides arc extinction reliability in different scenarios, which boosts its safety and dependability.

Applications of VCBs

Because of their longevity and low maintenance requirements, VCBs are adopted in numerous industries. Below are the key application sectors:

- Power Distribution Systems

VCBs are common features of medium voltage switchgear, where they offer circuit protection against faults. They help in a safe and stable power distribution in metropolitan areas as well as industrial zones.

- Industrial Facilities

In heavy industry and manufacturing plants, large electrical equipment such as motors and transformers is guarded by VCBs. Their potent arc control ensures equipment protection from faults and short circuits.

- Commercial Buildings

VCBs protect lighting, HVAC modules, and elevators in malls, offices, and hospitals. They enable operations in busy areas while also providing rapid fault isolation if needed.

- Renewable Energy Plants

Wind and solar power plants utilise VCBs for switching and fault protection. These breakers are capable of managing fluctuating loads.

- Utilities and Substations

Electric VCBs in substations aid electric utilities in safe load control and fault handling. Well, they are important parts in the control of power flows and the protection of infrastructure.

3) Comparison between ACBs and VCBs

Although both circuit breakers are protecting from faults, there are still many differences between them, which will compel you to decide between them. So, let’s start now!

i) Arc Quenching Principles

Variations in the methods of arc quenching directly affect the difference in performance. For instance, VCBs have the advantage of the simplicity and stability offered by the vacuum medium compared to ACBs, which put considerable effort into air pressure maintenance as well as the functioning of the arc chute.

ACBs have a shorter service life and require a lot of maintenance work when compared to VCBs. In addition to this, VCBs cut off electrical current much faster and more consistently than ACBs, demonstrating that arc quenching speed and efficiency are other areas where VCBs outperform ACBs.

- Advantages and Disadvantages

Due to the nature of the medium used to extinguish arcs for VCBs, they typically outperform ACBs in terms of arc extinction efficiency. As there is no air leakage or explosions possible, safety is also improved in VCB when compared to the ACB systems, which rely on air.

From a maintenance perspective, ACBs have more rigorous commitments, such as monitoring air pressure, clearing arc chutes, etc., while VCBs are relatively maintenance-free. With specific low-voltage applications that are not as rigorously designed, ACBs might be cost-effective. While long-term savings through maintenance with VCB are available, the starting cost is higher.

iv) Voltage Range

Air Circuit Breakers (ACBs): ACBs are prevalent in low to medium voltage levels. They operate around 380V to 690V and in some instances up to 1,000V. These are preferred for low-voltage power distribution in commercial and industrial facilities.

Vacuum Circuit Breakers (VCBs): VCBs have a wider application in medium to high voltage systems. They generally span from 3.3kV to 36kV, and at times even beyond. They are appropriately used in medium-voltage switchgear in power plants, substations, and large industrial complexes.

v) Construction and Components

Air Circuit Breakers (ACBs): ACBs incorporate arc chutes, moving contacts, and air-blast mechanisms. They take up more space and thus have greater exposure to the environment. Such designs are prone to failure without proper maintenance.

Vacuum Circuit Breakers (VCBs): The reliability of VCBs is enhanced since all the processes of arc extinguishing occur inside the vacuum chamber. Their construction adds to the overall stability of vacuum circuits, which, together with their long life, makes VCBs useful.

vi) Maintenance Requirements

Air Circuit Breakers (ACBs): Regular servicing is critical in ensuring ACBs operate reliably. Maintenance is required for the ACB components, and these include the arc chutes, air chambers, and contacts. It is also necessary to check the functionality of the air pressure system, as it must function properly for the Air Circuit Breakers to be useful during faults.

Vacuum Circuit Breakers (VCBs): The enclosed and sealed construction of VCBs makes them one of the easiest types of breakers to maintain. Vacuum interrupters have a high mean time between failures (MTBF), which means they will not need much servicing.

vii) Cost Considerations

Air Circuit Breakers (ACBs): Because ACBs start off with a low sticker price, they look great in tight budgets for low-voltage jobs. Dirty arc chutes, worn seals, and the air-pressure system all demand frequent servicing.

Vacuum Circuit Breakers (VCBs): Initial spending on VCBs is steeper because of the advanced materials and sealed design. Yet that upfront hit is mostly balanced out by savings in the long run. The sealed chamber keeps moisture and dust away, so serious faults are rare and service intervals stretch out.

| Feature | ACB (Air Circuit Breaker) | VCB (Vacuum Circuit Breaker) |

| Arc-Quenching Medium | Pressurized air | High vacuum |

| Arc-Quenching Principle | Arc split and cooled by air & arc chutes | Arc extinguished as metal vapour condenses in a vacuum |

| Voltage Range | 380V to 1000V (low to medium voltage) | 3.3kV to 36kV and above (medium to high voltage) |

| Construction | Bulkier with exposed parts: air chambers, arc chutes | Compact, sealed vacuum chamber |

| Maintenance | Regular maintenance needed (air system, contacts, arc chute cleaning) | Minimal maintenance; long lifespan due to sealed vacuum system |

| Initial Cost | Lower | Higher |

| Long-term Cost | Higher due to maintenance | Lower due to reduced servicing and logevity |

| Safety | Prone to air leakage and pressure issues | High safety due to enclosed and stable |

| Application | Commercial buildings, low-voltage systems | Substations and industrial plants |

4) Choosing the Right Circuit Breaker

Choosing the correct circuit breaker is important to get the right balance between safety measures, productivity, and expenditure. Moreover, if you are dealing with a small commercial panel or a large industrial system, your selection between the Air Circuit Breaker (ACB) or a Vacuum Circuit Breaker (VCB) alters the situation completely.

- Consider Your Voltage Needs

First, check the voltage limits for your system first. ACBs are used in low-voltage applications under 690V. VCBs are better suited for medium to high voltage applications, from 1kV up to 36kV or further than this.

So, if you’re in charge of heavy-duty machinery or high-voltage lines, then VCBs are more appropriate.

- Think About Maintenance and Downtime

Maintenance is another important aspect. ACBs require frequent maintenance. You will need to attend to the air pressure, the arc chute cleanup, and inspect numerous parts on a routine basis. As such, ACBs offer lower benefits when compared to VCBs.

VCBs are not labour-intensive because their sealed vacuum interrupters need less service and have a log life. This makes VCBs in high demand, especially where long downtimes are not acceptable.

- Look at Your Budget—Now and Later

Cost plays a vital role in most scenarios. ACBs seem pocket-friendly at first because of their lower start-up costs. However, maintenance costs eventually offset these savings.

Even though VCBs pose more cost at the start, in the long run, they are more economical due to lower service costs and a long operational lifespan. As a rule of thumb, focus on long-term benefits rather than short-term gains.

- Application Matters

Well, each system has its own distinctive features and requirements. ACBs are suitable for use in commercial buildings and offices. As for VCBs, they are best used in factories and substations or any other high-load environments demanding high reliability.

5) Final Words

So, the decision to select an Air Circuit Breaker (ACB) or a Vacuum Circuit Breaker (VCB) is made based on the requirements of the system’s voltage, maintenance attention, and total expenditure in the long run. As for ACBs, these breakers work best for low-voltage systems and are cheaper to purchase, though they do not require any maintenance work.

On the other hand, ACB’s Circuit Breakers come with sealed, lifetime vacuum interrupters that need low maintenance. Well, this makes them very suitable for dependable medium-voltage applications.

If you are looking to upgrade your equipment or for those wanting to design a rugged system, Eberry’s circuit breakers provide strong, flexible, and reliable solutions that are built to last. All the equipment is made of high-quality material with high-performance efficiency. Click here to contact Eberry right now.