A vacuum circuit breaker (VCB) is an advanced type of circuit breaker that uses a vacuum as the arc-quenching medium. Known for its high reliability, long service life, and eco-friendly operation, it is widely used in medium- and high-voltage applications. This guide explains what a VCB is, how it works, key advantages, common applications, and how it compares with other breakers.

1) What Is a Vacuum Circuit Breaker?

A vacuum circuit breaker interrupts electrical current by extinguishing the arc inside a vacuum chamber. The vacuum environment has extremely high dielectric strength, enabling the breaker to quickly suppress the arc and restore insulation. For a brief primer, see our overview: Vacuum Circuit Breaker Guide.

2) Structure & Key Components

- Vacuum Interrupter — A hermetically sealed ceramic or glass envelope with fixed and moving contacts. A metallic bellows enables contact movement while maintaining vacuum integrity. Arc shields prevent metal vapor from contaminating insulation.

- Operating Mechanism — Provides rapid and consistent opening/closing of contacts under fault conditions.

- Insulation & Housing — Coordinates creepage/clearance distances, withstands mechanical stress, and ensures long-term dielectric performance.

3) How Does a VCB Work?

- Arc Initiation — When contacts separate under load or fault, an arc forms in the interrupter.

- Arc Extinction in Vacuum — With no ionizable medium, the arc consists mainly of metal vapor; after current zero, the vapor rapidly condenses on nearby surfaces and dielectric strength recovers almost instantly.

- Current Zero Interruption — In AC systems, natural current zero aids interruption; the vacuum environment prevents re-strike.

- Arc Control by Contact Design — Grooved or spiral contacts make the arc rotate, distributing heat evenly and reducing erosion, extending service life.

4) Advantages of a Vacuum Circuit Breaker

| Advantage Category | Description |

|---|---|

| Compact & Economical | Smaller footprint and simpler construction compared to many air or gas designs. |

| Low Maintenance & Long Life | “Sealed-for-life” interrupter design reduces servicing and operational costs. |

| Eco-Friendly | No greenhouse gas handling (unlike SF6), supporting sustainability goals. |

| Fast, Reliable Interruption | Rapid dielectric recovery after current zero ensures stable fault clearing and reclose capabilities. |

5) Applications & Internal Product Links

Vacuum circuit breakers are used across medium- and high-voltage systems, including industrial facilities, utilities, and renewable energy plants. Explore representative Eberry Electric solutions:

- VS1 Indoor High-Voltage VCB (12 kV) — Suited for frequent operation and short-circuit interruption.

- Outdoor VCB Series — Designed for harsh climates and outdoor substations.

- Three-Position Combined VCB — Integrates disconnector and earthing functions for compact switchgear layouts.

- ZN-85 40.5 kV Indoor VCB — For power plants, substations, and mining applications.

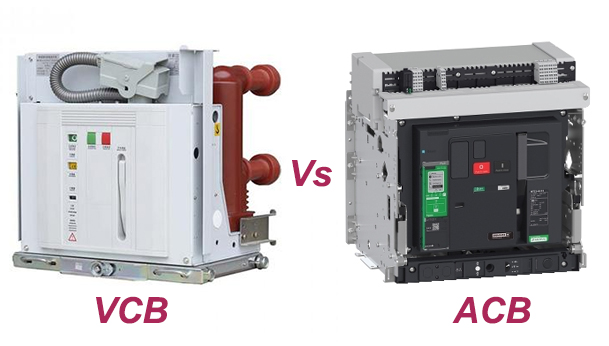

6) VCB vs Other Circuit Breakers

| Feature | Vacuum Circuit Breaker | Air Circuit Breaker | SF6 Circuit Breaker |

|---|---|---|---|

| Arc Medium | Vacuum | Air | SF6 Gas |

| Maintenance Needs | Very Low | Moderate | High (Gas handling) |

| Environmental Impact | No GHG handling | No GHG handling | High GHG impact |

| Size & Compactness | Compact | Larger | Compact |

| Lifespan | Long | Medium | Long |

Related reading (internal): Air Circuit Breaker vs Vacuum Circuit Breaker.

7) Why Choose Eberry Electric?

- 12+ Years of Manufacturing Experience in VCB design and production.

- ISO 9001, ISO 14001, ISO 5001 certified quality, environmental, and energy management systems.

- Products tested against relevant IEC and CE requirements.

- Global project references across Asia, Europe, and Africa.

- Custom engineering support for unique application requirements.

Contact us for technical consultation or a tailored quotation.

8) External References (Authoritative/Encyclopedic)

FAQ

What voltage range are VCBs typically used for?

Commonly in medium-voltage systems (e.g., 1–40 kV depending on design and standards). Check product datasheets for exact ratings.

How is a VCB different from an SF6 breaker?

VCBs use vacuum as the arc-quenching medium and avoid greenhouse gas management; SF6 breakers use SF6 gas and require gas handling procedures.

What standards apply to VCBs?

Products are validated against relevant IEC standards for AC circuit breakers and switchgear. Verify the exact standard edition in the product documentation.

What maintenance do VCBs require?

Minimal routine inspection (mechanism checks, functional tests) due to sealed interrupters; intervals depend on operation count and environment.