Reliable electricity distribution for industries, businesses, and utilities is crucial. But how can you guarantee safety, efficiency, and the smooth flow of operations? Medium Voltage switchgear is the answer. It secures electrical systems, mitigates failures, and keeps operations seamless. Whether you are an engineer, facility manager, or a business owner, knowing MV switchgear is vital. Let’s consider its structure, types, and applications so that you can make informed decisions!

1) What is Medium Voltage (MV) Switchgear?

Medium Voltage (MV) Switchgear is an electrical system aimed at controlling, protecting, and isolation electrical equipment working between 1kV and 36kV. It facilitates the non-stop and effective flow of electricity in industrial, commercial, and utility applications.

Switchgear is central to averting electrical faults such as short circuits and overloads. It identifies faults in the system and separates damaged areas. Therefore, the time it takes to repair the system and safeguard the operational equipment is minimized.

An MV Switchgear system comprises several main components: circuit breakers, busbars, protection relays, enclosures, and isolating switches. All these components are integrated to support safety and reliability during power distribution.

What is medium voltage switchgear

Performance is optimized in MV switchgear by applying various insulation techniques. There are three major categories which include air-insulated switchgear (AIS), gas-insulated switchgear (GIS), and solid-insulated switchgear (SIS). Each type provides distinct advantages depending on the requirements for application.

Well, we can say it is one of the most important elements of contemporary power systems because of its capacity to deal with large electrical loads with minimum hazard. More recently, MV switchgear incorporates modern technology such as intelligent monitoring systems, which also improves efficiency and maintenance.

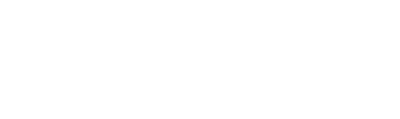

2) Structure of Medium Voltage Switchgear

Medium Voltage (MV) switchgear is composed of several parts that are fundamental for effective and safe power distribution. Each component is critical in the control of electric flow, fault management, and equipment protection.

Structure of medium voltage switchgear

- Medium Voltage Switchgear Components

- Circuit Breakers: These devices are tasked with disconnecting power automatically during faults such as short circuits or overloads. They allow system damage control and maintenance of system stability. These are vacuum, SF₆ and oil circuit breakers.

- Disconnect switches: These are used for manual separation of certain sections to enable maintenance work or automatic emergency shutdowns, making safe operation possible.

- Busbars: These are the parts that move conductive electricity between switchgear elements. They are built of copper and aluminium which guarantees optimal transportation of energy without losses.

- Protection Relays: These identify problems with the system and provide commands to open circuit breakers to disconnect the power, minimizing failures and downtimes for the whole system. The most recent relays allow for efficiency improvements through automatic supervision.

- Enclosures: These are components created to cover and protect sensitive parts or parts that can be damaged by dust, water, or touched accidentally. They are specially designed to improve safety and mechanical strength when used indoors or outdoors.

- Insulation methods

- Air-Insulated Switchgear (AIS): This type uses air as the insulating medium. It is widely used as it is economical, easier to keep, and popular in industrial buildings, but on the downside, It tends to occupy a larger area to perform effectively.

- Gas Insulated Switchgear (GIS): Compact solution utilizing SF₆ gas insulation which in particular makes it highly dependable. Because of that, it is perfect for areas with limited space, although proper handling of the gas is necessary.

- Solid Insulated Switchgear (SIS): An eco-friendly option. More reliable because it uses epoxy or polymer insulation eliminating gas usage. Minimally requires upkeep.

MV switchgear structure is made to be optimally effective, safe and flexible. The selection of which to use is based on the operational requirements and volume and nature of the environment that surrounds it.

3) How MV Switchgear Works

MV Switchgears serve the purpose of controlling, protecting and distributing power. It monitors the flow of power and isolates problematic areas whenever necessary. Power supplied is dependable and secure, making it applicable for industrial, commercial, and utility networks.

Working of medium voltage switchgear

The flow in MV Switchgear begins with busbars, which are assemblies of several conductive bars used to distribute energy to different circuits. They serve as a bolt that connects different parts of the system and ensure that power is transferred effectively. Protection relays scan the MV switchgear for problems continuously.

An identified problem sends a signal to the circuit breaker which stops power flow to prevent any harm from happening. Moreover, if a part of the system needs maintenance or adjustment, disconnect switches give operators the capability and flexibility to isolate specific areas of the network while leaving the system on. This prevents turning off ideally other components of the whole system.

Integrating protection, control, and fault detection enables the MV switchgear to maintain stability in the system, avoid electrical failures, and efficiently manage power in various industries.

4) Types of Medium Voltage Switchgear

MV switchgear differs with respect to insulation methods, construction features, and flexibility of operation. Each type is designed for specific applications and environmental conditions.

i) Air-Insulated Switchgear (AIS)

AIS uses air as an insulating medium between live parts. Its low cost, ease of maintenance, and relatively good efficiency have made it widely in use. It has drawbacks like it needs more space and is sensitive to dust and humidity.

ii) Gas-Insulated Switchgear (GIS)

GIS is more reliable than AIS since it uses SF6 gas for insulation. This enables a compact design. It is best in locations with limited space, like urban substations and industrial plants. While GIS requires lesser maintenance, it needs careful monitoring and handling for the SF6 gas for environmental concerns.

iii) Metal-clad vs. Metal-Enclosed Switchgear

- Metal-Clad Switchgear: This type of mv switching offers the best protection as each of its components is housed in a separate grounded metal compartment. Each component including the circuit breakers, relays, and busbars has a compartment VAT. This greatly enhances the safety, simplifies the maintenance and allows rotative replacement of parts.

- Metal-Enclosed Switchgear: The enclosure design is compact as it has no barriers. The enclosure design is compact but it has little isolation of sections.

iv) Fixed vs Withdrawable Switchgear

- Fixed Switchgear: The cost of fixed design with permanent mounting of circuit breakers and other switches is low but the circuit breakers cannot be maintained without shutting down the system for longer periods. This increases the downtime to maintain the equipment.

- Withdrawable Switchgear: Maintenance of circuit breakers is much easier as they can be swapped out for fresh ones without having to power down the entire system. It allows improved flexibility and efficiency in maintenance.

Deciding on an MV switchgear is based on space, maintenance capability and safety operational needs.

5) Applications of Medium Voltage Switchgear

Power utility MV switchgear is very important for controlling and protecting electrical systems in MV substations. It provides distribution and protection for most faults and reduces the chance of equipment damage due to malfunctioning components.

- Power Generating Plants

Singel line MV switchgear is utilized for the transmission of electrical energy from power plants. The plants can be thermal, hydro, or nuclear stations and the switchgear controls the voltage levels. It also isolates faulty circuits and enables the stable transmission of power to the grid.

- Industrial Manufacturing plants

MV switchgear is widely used in factories and processing plants for control, protection and power supply of the electrical motors driving conveyors and automated production lines. It also prevents overloading and protects electrical equipment, enabling smooth operational continuity and safety for workers.

- Commercial Structures and Data Centers

For optimal power distribution in large office structures, shopping centers, and data centers, MV switchgear is employed. It averts power surges that would otherwise ruin delicate equipment, like servers and HVAC units.

- Renewable Energy Systems (Solar Farms & Wind Farms)

MV switchgear is crucial for maintaining renewable energy resources. It allows for the integration of Solar panels and wind turbines into the power networks while controlling their voltage rises to avoid system breakdowns.

- Utility Distribution Networks

MV switchgear is used by electric utilities to manage power distribution from substation service to residential, commercial, and industrial customers. It guarantees a seamless power flow while containing malfunctioning zones to decrease service interruptions.

MV switchgear supports modern infrastructure by protecting electrical systems and enhancing their operational efficiency, ensuring the reliability of energy supply across multiple sectors.

Raghunath Rompicerla shared in their Quora post the wide applications of medium voltage switchgear that can be used in domestic and industrial applications. He further said that they can also be used to control transformers and motors. They are also seen in shopping malls, large offices, and other sites.

6) Key Considerations for Selecting Medium Voltage Switchgear

To ensure the safety, reliability, and operational efficiency of a power distribution system, power MV switchgear selection requires utmost attention. Some considerations need to be addressed prior to making this selection.

! Voltage and Current Ratings: The switchgear needs to be compatible with the voltage and current parameters of the system. Having the right ratings will ensure stable operation and overload prevention.

! Insulation Type: MV switchgear can be fitted with air insulation (AIS), gas insulation (GIS), or solid insulation (SIS) types. GIS is more reliable and compact while also being more expensive due to its use of SF6 gas, while AIS is cheaper and takes up more space. Lastly, SIS has a low carbon footprint and does not require as much maintenance as the other options.

! Installation Space and Environment: If there are space restrictions, the choice of switchgear is limited. Both types of GIS switchgear can be used in compact indoor spaces, whereas AIS switchgear is better suited for open areas. More extreme environments, such as those that are very humid or have a lot of dust, require switchgear with strong and robust enclosures.

! Maintenance and Accessibility: While fixed switchgear does not require as much downtime to make adjustments, it also requires more work during maintenance periods. Conversely, withdrawable switchgear can have components replaced quickly, but in turn, requires longer periods for the entire system to go online.

! Safety and Protection Features: Reliable switchgear is equipped with protective circuit breakers. It is possible to provide better protection with the use of fully covered metal-clad switchgear having isolated compartments.

! Cost and Lifecycle: Consideration of initial construction cost, effectiveness during operation, and after-construction service expense need to be taken as a whole. In this regard, more economical are more durable switchgear, which consumes small amounts of maintenance resources in the operating period.

In the end, the aid that a well-implemented MV switchgear brings is increasing the power distribution stability, and safety level, and greatly reducing operational risks.

7) Why choose Eberry Medium Voltage Switchgear

The selection of Medium Voltage (MV) switchgear is important for effective and safe power distribution. Eberry Medium Voltage Switchgear is the most preferred because of its design quality, technology sophistication, and reliability.

- Features Enhanced Safety and Protection: For electrical safety, Eberry MV switchgear comes with advanced protection relays, arc fault detection, and high-performance circuit breakers. The design adheres to International safety standards, providing safe operations for different sectors.

- Exceptional Insulation Options: Eberry provides Air Insulated Switchgear (AIS), Gas Insulated Switchgear (GIS), and Solid Insulated Switchgear (SIS). All these options help customers choose the most appropriate insulation type considering space, budgetary, and environmental constraints.

- Exceptional Insulation Options: Robust and low maintenance Eberry switchgear is constructed for a long service life while having minimum maintenance. Components are enclosed in robust cases made of high-quality materials which protects them from dust, moisture, and extremities of temperatures, hence reducing downtime and operational expenditure.

- Ease of Installation and Configuration: Eberry offers withdrawable or fixed switchgear for easier upgrades and maintenance. The switchgear can be used in tailored designs for industrial plants, commercial buildings, and power utilities.

- Internationally Trusted Industries: Eberry MV switchgear is in extensive use in power plants, factories, data centers, and renewable energy systems because of its reputation for being reliable, efficient, and innovative.

If you are looking for an MV switchgear that is safe, durable, and efficient, Eberry comes on top. For more details, visit Eberry Medium Voltage Switchgear.

8) FAQ

1. Why is switchgear needed?

Switchgear controls, protects, and isolates electrical equipment which prevents a fault, overload, or short circuits. It establishes safe distribution of power, lessens downtime, and improves system reliability in industrial and commercial practices.

2. What is the difference between switchgear and switchboards?

Switchgear comes with circuit breakers that can manage higher voltage, unlike switchboards which are only capable of enforcing low-voltage power distribution within a facility. In addition, switchgear offers advanced protection and fault isolation which is absent in switchboards.

3. What is the life expectancy of a medium voltage switchgear?

Medium Voltage switchgear can be used for twenty to thirty years with constant maintenance and care in usable conditions. Timely inspection and upgrades along with effective utilization should improve dependability and lifespan.

9) Conclusion

Medium Voltage switchgear can contribute to safe and effective power distribution across different industries. Knowing its structure, types, and applications greatly aids in making the correct selection. Opting for high-quality switchgear improves the reliability and longevity of the system. Eberry is your solution for high-end MV switchgear that is durable and efficient. We invite you to check our website for more information.