When choosing between an oil circuit breaker and a vacuum circuit breaker, it can be daunting due to factors such as cost, safety, and maintenance. If you are also confused, don’t worry. This article provides practical recommendations based on real-world scenarios to guide you in making the most suitable choice.

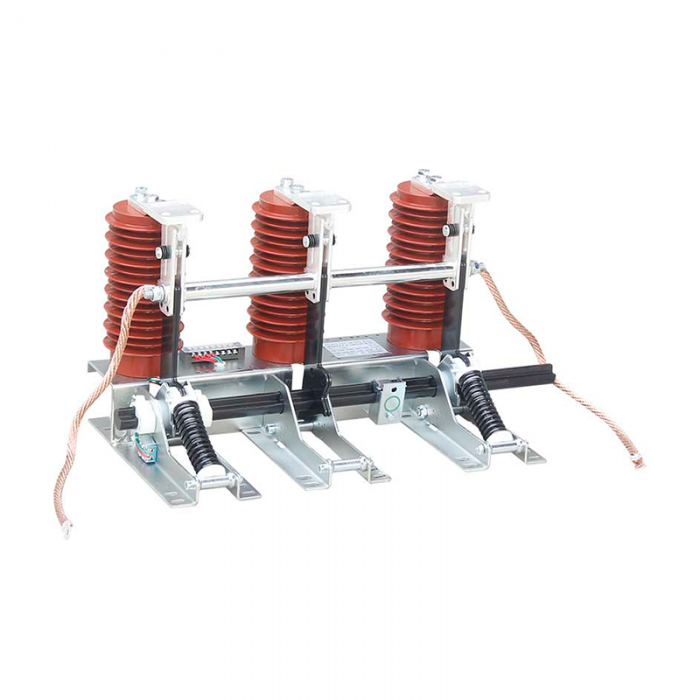

1) What Are Vacuum Circuit Breakers?

“A Vacuum Circuit Breaker (VCB) is one of the types of electrical circuit breakers that employ a vacuum medium to quench the arc produced during gas exchange while breaking the current, especially under fault conditions.”

Simply, the vacuum circuit breakers are used for safely stopping current flow. Thus, it is one of the most reliable electrical circuit breakers available, particularly for medium-voltage systems.

The secret is its arc-quenching method. Yes, unlike older versions that utilised oil or gas, this model uses a vacuum. The advantage of a VCB is that it is much cleaner and more reliable. Moreover, its long life is an additional benefit.

How a Vacuum Circuit Breaker Works

A vacuum circuit breaker prevents an electric arc from forming in a circuit by using a vacuum to interrupt it. This occurs in a small sealed chamber called a vacuum interrupter.

Here’s what happens step by step:

- Normal operation: Whenever the power system is functioning correctly, the breaker’s internal contacts remain closed. Electricity flows through the contacts without any problems.

- Fault occurs: Breakers are designed to open for interruptions such as a short circuit or overload.

- Contacts open: During a fault, if you look at the contacts of this breaker, they begin to separate, and you can see an electric arc buzzing between them, indicating that separation is underway.

- Arc quenching: Because the arc is surrounded by a vacuum, any air that it could use to survive is effectively absent. The arc becomes weak and extinguishes while the current goes to zero.

- Power stops: Once the arc dies, the flow of current ceases entirely. The system is no longer exposed to any danger, and no damage will occur if the breaker is reset.

- System recovery: After resolving the issues, the circuit breaker can be reset, and normal system operation can resume.

The entire sequence described above takes only a few milliseconds to complete. This makes vacuum switchgears excellent choices for MV circuit breakers as they are safe, efficient, and do not require oil, gas, or other insulating materials.

Why You’ll prefer It

Everyone prefers solutions that are simple, effective, and problem-free. The vacuum circuit breaker fulfils those needs. It has low maintenance demands as it does not require oil breaker tanks or gas refills, and is not hindered by dust and moisture.

Another reason is that its speed and quiet operation make it of great use for repetitive tasks. When used for load switching, this breaker has a long operational life.

Reinstallation of old oil breakers is also simple with new systems. With many power engineers nowadays replacing oil circuit breakers with vacuum ones, it is easy to see why.

2) What Are Oil Circuit Breakers?

If you are working with high-voltage systems, you may have encountered oil circuit breakers. They are one of the earliest types of electrical circuit breakers and are still prevalent in numerous power networks globally.

As is evident from the name, these breakers utilise circuit breaker oil—also called breaker oil—as a medium for fault handling. This special oil serves two key jobs: it prevents electric arcs from forming and insulates the live parts.

Although newer technologies such as vacuum circuit breakers and gas circuit breakers are gaining prominence, oil circuit breakers continue to be useful, particularly in older or more remote systems. Let’s discuss it a bit further.

How an Oil Circuit Breaker Works

You may be wondering, how does oil stop electricity? Let’s explain.

- Normal operation: While everything functions as it should, current flows through the breaker’s contacts, which are closed, similar to other electric circuit breakers.

- Fault detected: A fault occurs, such as a short circuit or overload, and the breaker will open.

- Contacts open: When the contacts are separated, an electric arc is produced between them. This arc, if permitted to persist, poses a substantial risk.

- Oil to the rescue: Here is where the breaker oil plays its role. The arc heats the oil, and that oil then breaks down into gas heated to a layer around the arc. That gas, which is primarily composed of hydrogen, cools and extinguishes the arc.

- Arc vanishes: With no more arc, current ceases to flow. Power has been safely disconnected by the oil circuit breaker.

- Resetting: Once the fault is rectified, the breaker can be reset and the system put back to use.

This approach works, but there’s a problem. The oil circuit breaker needs frequent checks on its oil levels. There is a possibility for the oil to oxidate, or in very extreme conditions, even ignite. That is why precautionary measures and consistent maintenance are essential.

Why You Might Still Use an Oil Circuit Breaker

Even with newer alternatives such as air circuit breakers, SF6 circuit breakers, and vacuum switchgear, the oil circuit breaker still proves to be useful in some scenarios. If your system is designed to accommodate oil breakers, it may not be prudent to replace everything immediately.

Additionally, for certain high-voltage applications, circuit breaker oil provides exceptional dielectric strength. Just remember: it requires care and attention.

3) Vacuum Circuit Breakers vs Oil Circuit Breakers: Key Comparison Factors

If you are looking at getting either an oil circuit or a vacuum circuit breaker, the decision might be difficult due to a number of reasons. However, we are going to outline the basic elements relating to the two which we know would be important to you.

i) Arc Quenching Method

This is the core of every circuit breaker.

A vacuum circuit breaker breaks the arc using a vacuum environment at the contact separation. No air, no oil, just a chamber where the arc exists is evacuated.

In contrast, an oil circuit breaker uses the oil contained in the breaker to extinguish the arc. The liquid oil turns into vapour due to the heat from the arc, and this vapour cools to quench the arc.

ii) Maintenance Needs

This might make you happy – vacuum switchgear has no upkeep requirements. Since there is no oil to replenish, gas to refill, or leaks to be concerned about, everything is smooth sailing!

On the other hand, oil circuit breakers have their downsides. Regular servicing, such as oil testing, cleaning, and monitoring, is mandatory. If left unchecked, the oil used in circuit breakers may stagnate and degrade, leading to improper functionality.

iii) Safety

Vacuum takes the crown once again. There is no fire danger due to the absence of oil. For this reason, vacuum circuit breakers are perfect for indoor and confined places.

There is a disadvantage to oil circuit breakers, however. Oil overheating or oil leaks overheating poses a risk of fire or explosion. Because of this, additional safety measures need to be installed.

iv) Size and Weight

If you need compact, then a vacuum is the answer.

MV circuit breakers in vacuum are easier to install, and are smaller and lighter. In contrast, oil breakers have larger tanks and heavier parts because of the oil insulation system.

v) Environmental Impact

A vacuum circuit breaker is green. It does not require oil, which needs proper disposal, nor does it use gas like SF6 circuit breakers do.

In the meantime, oil used in circuit breakers is harmful to the environment if not managed appropriately. Leaks, spills, and disposal are always potential issues.

vi) Cost and Lifespan

At first, a vacuum may seem pricier. In the long run, it saves you money due to almost zero maintenance.

While oil circuit breakers have a lower initial cost, there are ongoing expenses related to oil maintenance, testing, and repairs.

vii) Ideal Applications

For medium-voltage systems with high-frequency switching, vacuum is best. It also serves modern grids and is good for commercial use.

Oil circuit breakers perform well in high-voltage systems and legacy systems. Some equipment can often be maintained at less cost than replacing it, making immediate replacement impractical.

| Factor | Vacuum Circuit Breaker | Oil Circuit Breaker |

| Arc Quenching | Uses a vacuum to extinguishthe arc instantly | Uses circuit breaker oil to quench the arc |

| Maintenance | Very low maintenance | Needs regular oil checks and servicing |

| Safety | No fire or explosion risk | Fire risk due to oil overheating or leakage |

| Size & Weight | Compact and lightweight | Bulky due to the oil tank |

| Environmental Impact | Eco-friendly, no gas or oil | Used oil disposal is a concern |

| Cost & Lifespan | Higher upfront, lower long-term cost | Cheaper upfront, more upkeep costs |

| Best Use | Ideal for MV systems, indoor, frequent use | Suitable for high voltage, older systems |

4) Which Is Better: Application-Based Recommendations

Having discussed the differences between vacuum and oil circuit breakers, the question that arises now is ‘which one should you go for?’ The answer will vary depending on your circumstances. Let us analyse some scenarios to help make your decision easier.

! Medium Voltage Systems (Up to 36kV)

In the case of most MV circuit breakers, vacuum circuit breakers dominate by a landslide. These breakers are compact, safe, and extremely easy to work with. Their performance in indoor environments such as offices, factories, and switchgear rooms is exceptional.

Today, oil breakers are seldom used for medium voltage applications because they are bulky, more difficult to maintain, and not ideal for confined areas.

Use vacuum circuit breakers for modern medium voltage systems.

! High Voltage Installations

Oil circuit breakers are still found in some high-voltage configurations, particularly in older networks. They are suitable for heavy load and high arc energy applications, particularly in low-density environments.

Keep in mind that more modern options, such as SF6 circuit breakers and advanced gas circuit breakers, also exist. These alternatives provide enhanced safety and minimised maintenance compared to oil.

If dealing with high voltage and older equipment, oil breakers could still be useful.

! Frequent Switching Operations

If the breaker needs to be switched on and off frequently, choose vacuum switchgear because it can sustain a large number of switching cycles.

These are not the best for frequently operated systems. The oil and contacts suffer greatly due to arcs formed over time, necessitating excessive maintenance.

In places where repeated switching is required, such as substations and industrial control panels, use vacuum circuit breakers.

! Remote or Unmanned Locations

Maintaining a system located in a hard-to-reach area poses a significant challenge. In this case, reliability is the most important quality to look for.

In this regard, a vacuum system would best suit your needs. As said before, vacuum circuit breakers do not use oil, meaning that there will be no chance of leakage, fire, or spillage.

With remote sites, vacuum circuit breakers are safer and smarter.

! Upgrading Old Systems

Still using oil breakers? You’re not alone. There are plenty of older systems equipped with breaker oil and gear. But this could be the perfect time to look for modern replacements.

Vacuum circuit breakers (VCB) are perfect for retrofit projects. Their compact form, high efficiency, and ability to withstand modern power demands make them suitable for almost any use case.

5) Transitioning from Oil to Vacuum Circuit Breakers

Using oil circuit breakers still? You’re not alone there either. Many older systems rely on circuit breaker oil for arc control. But as technology improves, more options become available. Moving to vacuum circuit breakers can save you time, reduce risk, and boost the efficiency of your electrical system.

Let’s explore how you can switch step by step.

i) Check Your System Voltage

First step is, you may need to check your system voltage.

For medium-voltage systems up to 36kV, a vacuum circuit breaker will usually work as the best replacement. These MV circuit breakers are modern, fast, and compact. Besides, they are designed to be used in contemporary industrial setups.

Gas circuit breakers and SF6 circuit breakers are alternatives to consider for high-voltage applications. For the majority of applications, however, vacuum circuit breakers are the safest and most convenient option.

ii) Look at the Existing Setup

Before any changes are made, it’s advisable to check if your panel or gear is compatible with the vacuum switchgear system.

Here’s some good news! Many vacuum breakers are made to slot into older oil breaker panels, and some companies also provide retrofit kits to simplify the process. While some modifications to control circuits and wiring may be necessary, it is relatively simple.

iii) Think About Safety and Maintenance

This is where the vacuum shines the most.

Routine testing and maintenance is needed on oil breakers. Overheating issues, oil leaks, fire danger, and general overheating is always worrisome. On the contrary, oil-less vacuum circuit breakers are sealed for life. There’s no oil, no mess, and no worries.

If you want a system that requires minimal supervision or routine care, go with a vacuum system.

iv) Plan the Cost, But Think Long Term

Sure, a vacuum circuit breaker might have a higher initial cost. But consider what value it brings.

No oil changes. No routine inspections. Fewer breakdowns and repairs.

Overall, reliability and cost effectiveness improve with the use of vacuum breakers.

While the initial investment may be more expensive, the long-term savings are much higher.

6) Conclusion

There is no doubt that both oil and vacuum circuit breakers have their respective uses, but the vacuum types very clearly stand out due to the safety benefits, minimised maintenance demands, and long-term cost savings.

When considering upgrading a system, it usually makes sense to incorporate vacuum circuit breakers because of their reliability, efficiency, and suitability for contemporary power requirements. VCBBreakers are well known for providing reliable and high-quality solutions. We have a wide range of advanced vacuum switchgears designed and manufactured to meet the electrical standards of today.

You can contact us right now!